Iron-Carbon Phase Diagram with

Detailed Explanation:

CATEGORIES:- Iron-Carbon Phases:

- γFe (Austenite)

- αFe (Ferrite)

- δFe (Delta Iron)

- Phase transformations in the Iron-Carbon Diagram

- Eutectoid Phase Transformation

- Eutectic Phase Transformation

- Peritectic Phase Transformation

- Peritectoid Phase Transformation

- Ledeburite

- Martensite

- Phase Transformation in Iron Carbon Diagram:

- Eutectoid Phase Transformation

- Eutectic Phase Transformation

- Peritectic Phase Transformation

- Peritectoid Phase Transformation

- Microstructure in Iron-Carbon Alloys:

- Microstructure of eutectoid steel

- Microstructure of hypoeutectoid steel

- Microstructure of hypereutectoid steel

- Reactions in Iron Carbon Phase Diagram:

- Eutectoid reactions

- Eutectic reactions

- Peritectic reactions

- Development of Microstructure in Iron-Carbon Alloys:

- Microstructure dependence on composition and heat treatment

- Microstructure of eutectoid steel

- Microstructure of hypoeutectoid steel

- Microstructure of hypereutectoid steel

- Limitations of Equilibrium Phase Diagram:

- Limitations of Fe-Fe3C equilibrium/metastable phase diagram

Iron-Carbon Phases:

If the percentage of the carbon is in the range of 0 to 2.11 % then it is called Steel and if the percentage of carbon is in the range of 2.11 to 6.67% then it is called Cast iron.

As the carbon content increases, it produces more Iron-Carbide volume and

that phase will exhibit high hardness.

About γFe: (Gamma(γ)Iron)

- γFe is also called

as “Austenite”

- The maximum solubility of carbon is

2.11 % at 1147 degrees centigrade.

- By varying carbon content from 0 to

2.11 % variety of Steels in the γFe phase can be obtained.

- By heating or cooling process

of γFe phase, the grain size can be modified(heat treatment) so

that a variety of phases with different strengths can be obtained.

- The hardness of

the γFe phase depends on the percentage of carbon that it

possesses.

- The minimum temperature about which

the γFe phase exists is 723-degree centigrade at 0.8 Percentage

of Carbon.

About

αFe: (Alpha(α)

Iron)

- αFe is also called as “Ferrite”.

- The maximum solubility of carbon is 0.025% at

723-degree centigrade.

- αFe possesses similar properties of pure iron but

hardness is slightly high compared to pure Iron.

- It is magnetic.

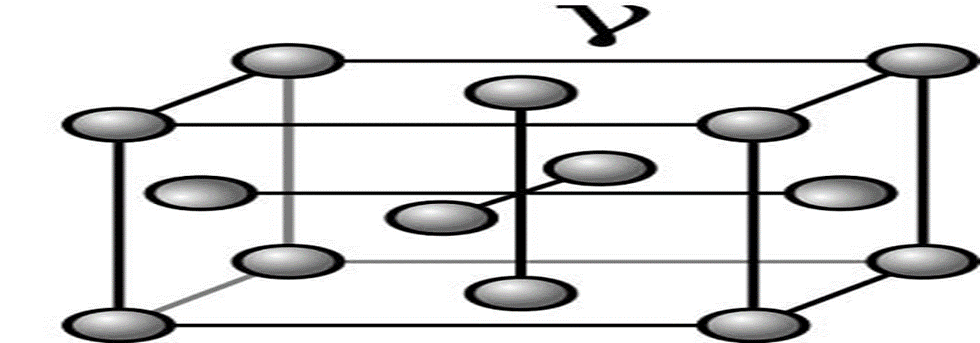

- The structure is BCC.

About

δFe: (Delta(δ) Iron)

The maximum solubility of carbon

is 0.1% at 1493 degrees

centigrade.

- Fe(δ-Iron) possesses very low carbon content and

thereby it possesses low hardness and that indicates it is a highly

ductile phase.

- Fe is difficult to produce and the most unstable

phase because the addition of very small carbon content in Iron(Fe)

lattice with uniform distribution is very difficult at high temperatures.

- The structure is BCC.

Phase

Transformation in Iron Carbon Diagram:

1.

The four Phase Transformations in

Fe-C Diagram are as follows.

Eutectoid Phase Transformation

2.

Eutectic

Phase Transformation

3.

Peritectic

Phase Transformation

4.

Peritectoid

Phase Transformation

The Detailed Explanation of all

the above phases is presented below.

Eutectoid Phase Transformation

Eutectoid Phase Transformation:

The Eutectoid Phase Transformation

is as follows.

At ‘S’ point: (Eutectoid Point)

S1--> [S2 + S3]

γFe-->[(αFe) +

Fe3C] at 0.8%C @723 Degree Centigrade

Note: (αFe) + Fe3C is

called as Pearlite.

n the Iron-Carbon Diagram, the

austenite phase(γFe) can undergo a Eutectoid transformation to produce ferrite and cementite called

as Pearlite.

Eutectic Phase Transformation:

The Eutectic Phase Transformation

is as follows.

At ‘C’ point:(Eutectic Point)

L (Fe+C)--> [(γFe) +

Fe3C] at 4.3%C @1147 Degrees Centigrade

L--> [S2 + S3]

A eutectic reaction is a

three-phase reaction, by which on cooling, a liquid transforms into two solid

phases at the same time.

Peritectic

Phase Transformation:

The Peritectic Phase

Transformation is as follows.

At ‘J’ point:(Peritectic Point)

(δFe+ L)--> (γFe) at 0.17%C @1493 Degree

Centigrade

(S1+L )-->S2

Peritectoid

Phase Transformation:

The Peritectoid Phase

Transformation is as follows.

(S1+S2 )-->S3

Note:

A mixed-phase of (γFe +

Fe3C) existing from 4.3% to 6.67% between 723 Degree Centigrade to 1145

Degree Centigrade is known as Ledeburate Phase.

Ledeburite

· is

the eutectic mixture of austenite and cementite.

· It

contains 4.3 percent Carbon and is formed at 1130°C. 7-Martensite –

· a

super-saturated solid solution of carbon in ferrite.

· It is

formed when steel is cooled so rapidly that the change from austenite to

pearlite is suppressed ( growth less).

Note :- · Steel

with 0.8% carbon is wholly pearlite phase only.

· steel

contains less than 0.8% carbon containing ferrite + pearlite which is hard.

· Steel

contains more than 0.8% carbon and (pearlite + cementite).

Reactions in Iron

Carbon Phase Diagram

There are Three Phase Reactions:- 1- Eutectoid reactions

0.76 wt% Carbon , at 727 °C

γ(0.76 wt% C) ↔ α (0.022 wt% C) + Fe3C

in Eutectoid reaction , the two-phase mixture (ferrite & cementite). They

are steels.

2- Eutectic reactions :

4.30 wt% Carbon , at 1147 °C

L ↔ γ + Fe3C

In Eutectic reaction , alloys called cast irons.

Eutectic and eutectoid reactions are very important in heat treatment of

steels.

3- Peritectic L + δ = γ

Peritectic reaction , at 1493 deg.C, with low wt% C alloys (almost no

engineering importance).

Development of Microstructure in Iron - Carbon alloys

Microstructure depends on composition (carbon content) and heat treatment. In

the discussion below we consider slow cooling in which equilibrium is

maintained. 1-

Microstructure of eutectoid steel 0.76

wt%C, 727 °C γ(0.76 wt% C) ↔ α (0.022 wt% C) + Fe3C

When alloy of eutectoid composition (0.76 wt %

C) is cooled slowly it forms perlite, a lamellar or layered structure of two

phases: α-ferrite and cementite (Fe3C). The layers of alternating phases in

pearlite are formed for the same reason as layered structure of eutectic

structures: redistribution C atoms between ferrite (0.022 wt%) and cementite

(6.7 wt%) by atomic diffusion. Mechanically, pearlite has properties intermediate to soft,

ductile ferrite and hard, brittle cementite. In the micrograph, the grey areas

Microstructure of hypoeutectoid steel

Compositions to the left of eutectoid

(0.022 - 0.76 wt % C) hypoeutectoid (less than eutectoid ) alloys.

γ → α + γ → α + Fe3C

Hypoeutectoid alloys contain proeutectoid

ferrite (formed above the eutectoid temperature) plus the eutectoid perlite

that contain eutectoid ferrite and cementite.Ledeburite

· is the eutectic mixture of austenite and cementite.

· It contains 4.3 percent Carbon and is formed at 1130°C. 7-Martensite –

· a super-saturated solid solution of carbon in ferrite.

· It is formed when steel is cooled so rapidly that the change from austenite to pearlite is suppressed ( growth less).

Note :- · Steel with 0.8% carbon is wholly pearlite phase only.

· steel contains less than 0.8% carbon containing ferrite + pearlite which is hard.

· Steel contains more than 0.8% carbon and (pearlite + cementite).

Reactions in Iron Carbon Phase Diagram

3- Microstructure of hypereutectoid steel Compositions to the right of eutectoid (0.76 - 2.14 wt % C) Hypereutectoid (more than eutectoid ) alloys. γ → γ + Fe3C → α + Fe3C

Hypereutectoid alloys contain proeutectoid cementite (formed above the eutectoid temperature) plus perlite that contain eutectoid ferrite and

cementite

Limitations of equilibrium phase diagram

· Fe-Fe3C equilibrium / metastable phase diagram.

· Stability of the phases under equilibrium condition only.

· It does not give any information about other metastable phases. i.e. bainite, martensite.

· It does not indicate the possibilities of suppression (reduced ) of proeutectoid phase separation.

· No information about kinetics energy.

· No information about size.

· No information on properties

Comments

Post a Comment